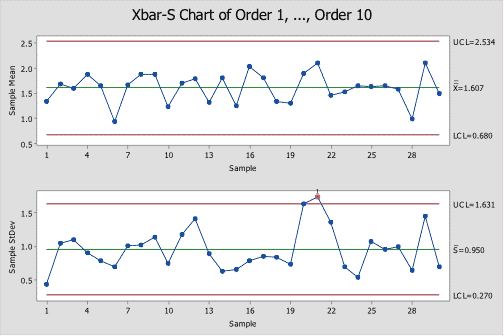

The control limits on the X-Bar brings the sample’s mean and center into consideration. X-bar chart: The mean or average change in process over time from subgroup values. The cumulative sum ( CUSUM) and the exponentially weighted moving average ( EWMA) charts are also monitors the mean of the process, but the basic difference is unlike X bar chart they consider the previous value means at each point. These combination charts helps to understand the stability of processes and also detects the presence of special cause variation. It is actually a two plots to monitor the process mean and the process variation over the time and is an example of statistical process control. X bar R chart is used to monitor the process performance of a continuous data and the data to be collected in subgroups at a set time periods. Selection of appropriate control chart is very important in control charts mapping, otherwise ended up with inaccurate control limits for the data. View source version on businesswire.X Bar R charts are the widely used control chart for variable data to examine the process stability in many industries (like Hospital patients’ blood pressure over time, customer call handle time, length of the part in production process etc.,). Lecture 4: Statistical Process Control: The ABC's of Control ChartsĮxponentially Weighted Moving Average (EWMA) chartsįor more information about this training visit Harmonization of regulations with FDA guidance/regulations Lecture 2: Regulatory Requirements in Quality Management Ishikawa, seven quality control tools (7-QC) and supplementals (7-SUPP)

Lecture 1: It's a System! Elements of Quality Managementĭeming 14 points for total quality managementĭr.

XBAR CHART MINITAB SOFTWARE

Eisenbeisz will make use of Minitab software in her presentation. This seminar will provide attendees with the statistical tools necessary to monitor processes to ensure the quality of manufactured products. Many industries are also required to have a good process management system in place to achieve compliance with regulatory authorities. A good system of processing and checks reduces costs associated with production waste and re-work due to defects, and allows a company to deliver products that are high in quality. Process control is important for a company's reputation. Statistical process control (SPC) allows us to control the functions of our processes (input) by providing tangible monitoring tools. However, sometimes the variation is excessive and this hinders the ability to achieve reliable measurements and desired results. The presentation of statistical charts and analyses, graphical techniques for planning, trouble-shooting and problem solving will also be presented.Īll processes exhibit intrinsic variation. Therefore, historical concepts, current trends and regulatory requirements will be discussed. Presented examples will include an emphasis on the manufacturing processes and quality assurance needs of product in the medical device and pharmaceutical industries. Although the presentation involves use of statistical techniques, presentation of statistical theory will be limited to only what is needed by the attendees to understand and implement processes and monitoring tools within the statistical framework.

The objective of the seminar is to provide information that can be used immediately by personnel involved in production operations, and by supervisors and management in decision making. An emphasis will be placed on the set-up and use of control charts. The concepts and information presented will be mainly concerned with statistical process control: obtaining monitoring information (data) that is objective, unbiased, and useful for decision making. This 6-hour virtual seminar includes a presentation of the steps and techniques used to quantify variability in manufacturing processes, and to assure quality products. The "6-Hour Virtual Seminar on Statistics for Process Control" training has been added to 's offering.

0 kommentar(er)

0 kommentar(er)